Also because everyone else in the MCAD industry is doing it.

Generative modeling came from Siemens AG’s need to minimize the weight of aircraft and vehicle components. NX 12 calls its “topology optimization” and it can work with meshes, surfaces and solids at the same time. Sexy because the result often looks creepily organic like a bone ( Figure 2).

#SIEMENS NX 12 SOFTWARE#

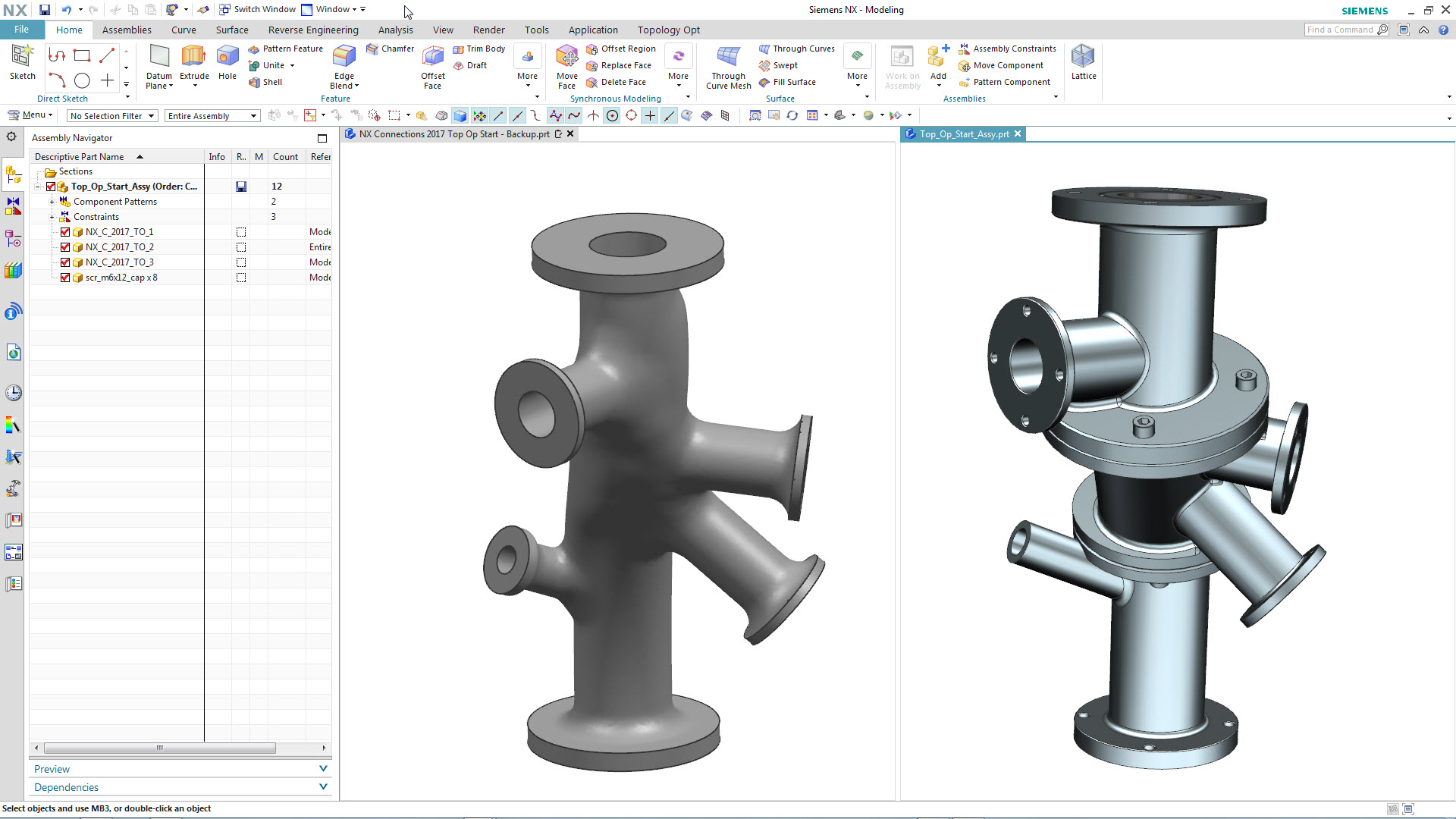

It also came about because arch-competitor Dassault Systemes’s Spatial division had already been working on its Polyhedra version of composite modeling.įigure 2: The frame of a car reduced in weight through generative modeling or “topology optimization” as Siemens PLM calls it.Sexier than composite modeling is generative modeling, where software repeatedly analyzes a part to minimize its volume while maintaining its strength. Composite modeling came from Siemens AG’s need to reverse engineer existing construction sites and then edit and add on to them. Typically, solid-only modeling operations – like selecting areas, removing features, filling in areas and adding fillets, are now possible with meshes. In NX 11, meshes could coexist with solids, but this year’s NX 12 performs about a half-dozen editing commands on meshes. Meshes are commonly the result of scanning real objects, whether a knee bone or an industrial plant, to create 3D wireframes.

#SIEMENS NX 12 HOW TO#

Just when you think CAD is settled, he said, something new comes along, like composite modeling.Ĭomposite modeling tackles a tricky problem that, just a handful of years ago, few thought could be solved – or even needed solving: How to edit 3D meshes as if they were solids. But unlike a mature market like SAP, where there is little left to innovate, he said that CAD is a mature market that still innovates due to the strong competition. “We are now in a replacement market, so we grow by taking business away from competitors,” he said. CEO Hemmelgarn claimed that, for the last six years, NX has outgrown its competitors by 4% a year.

The real star of the PLM Connections show, given it’s high profile at the event, was the release of NX 12. The PLM division got a nice bump in revenues following last year’s acquisition of Mentor, a $1.2-billion/year company that specializes in electrical CAD.ĭuring last June’s PLM Connection Americas conference in stinking-hot Phoenix (it was 42C the entire time), we in the CAD media were given a mind-numbing, 45-minute overview of how all of the PLM division’s software works together, from CAD design to operating the manufacturing floor. Siemens AG itself pulled in approximately $100 billion in revenues, last year. When measuring the size of the Siemens PLM Software division in revenues, it’s running at US$3.5 billion a year, a very close second to CAD vendor leader, Dassault Systemes. Siemens AG says it has 15.3 million users. In fact, all of the software that works with NX runs in NX, emphasizes Bob Haubrock, whose official title is Senior Vice President, Product Engineering Software but he prefers to introduce himself as “the guy in charge of NX.” When you have all this software at your disposal, what might be the primary function you would want? “Integration,” says Siemens PLM Software CEO Tony Hemmelgarn ( Figure 1). In response, the PLM division comes up with software that also works well for external customers. Siemens AG tells Siemens PLM Systems what it needs to design its lines of medical devices, electricity-producing windmills and high-speed bullet-style locomotives. A decade after Siemens AG purchased UGS, NX is now pervasive and symbiotic. When a manufacturing company has its own line of design and analysis software, it gets to eat its own cooking. As one Siemens PLM employee muttered during the recent PLM Connections user group event, the company now has “so much software that we don’t necessarily know what all we have.”

#SIEMENS NX 12 PLUS#

Manufacturing giant Siemens AG of Germany owns NX, Solid Edge and a host of supporting CAM, CAE, ECAD, and PLM programs – plus the crucial kernel and constraints programs Parasolid and D-Cubed. Today, no significant CAD software is owned by a manufacturer, although some manufacturers run in-house CAD systems strictly for internal use.

Unigraphics was enhanced by aircraft manufacturer McDonnell Douglas, and now is known as NX at Siemens PLM Software. Catia was developed by Dassault Aviation, and now is the flagship MCAD program for Dassault Systemes. Figure 1: Siemens PLM Software CEO Tony Hemmelgarn speaking at the opening keynote session at the company’s annual PLM Connection Americas 2018 Conference.Many MCAD software programs were incubated in the 1970s and 1980s by the colossi of manufacturing, but were later spun off when those players no longer wanted to be in the software business.ĬoCreate, for example, was created by HP but is now known as Creo by PTC.

0 kommentar(er)

0 kommentar(er)